In June, NASA’s Space Technology Mission Directorate announced that the Jet Propulsion Laboratory (JPL) would fly the Deep Space Atomic Clock payload aboard the commercial Orbital Test Bed satellite that is being developed by Surrey Satellite Technology US (SST-US) at the firm’s new Colorado assembly facility.

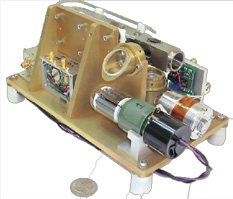

Artistic rendition of the Deep Space Atomic Clock. Image courtesy of NASA + JPL.

The announcement focused a much-deserved spotlight on an unheralded, yet critically important, type of spacecraft mission—the technology demonstration satellite.

These demonstration missions typically fall into two categories known as test beds and pathfinders. Sometimes referred to as a hosted payload mission, the test bed satellite usually carries multiple unrelated spacecraft components that are being flown on orbit for the first time. These components may be entirely new subsystems or improved engineering designs of traditional equipment that must prove their performance in the rigors of space before integration into large operational missions.

The Deep Space Atomic Clock (DSAC) is a prime example of a test bed mission. Atomic clocks are crucial for spacecraft navigation, and JPL is designing DSAC as a much smaller and more precise replacement for existing devices.

NASA’s objective is to test DSAC on orbit with a relatively inexpensive mission before installing another on a far more costly flight to outer space.

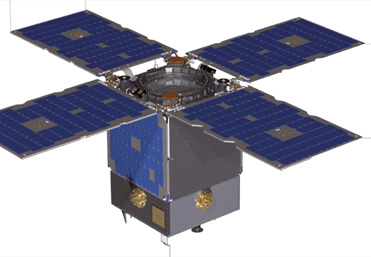

DSAC will be launched in 2015, along with eight other payloads, aboard the commercial Orbital Test Bed (OTB), which will be owned and operated by SST-US. As is often the case with test bed missions, the OTB satellite will use a flight-proven design, the SSTL-150, developed by SST-US’ parent company in the United Kingdom, Surrey Satellite Technology Ltd.

While the Surrey name is most often associated with operational satellite missions, 33 of its 41 launches have involved demonstrations of remote sensing, navigation, and communications technologies.

The other type of demonstration mission, the pathfinder, is usually more technically complex, often involving multiple new or redesigned components that must be tested together as an integrated subsystem. These components may relate to the operation of the satellite or to its mission, such as a new imaging sensor on a remote sensing satellite. In some cases, a pathfinder may be a scaled-down version of a multifunction satellite that meets the minimum requirements of the proposed larger mission.

Whether the demonstration mission is a test bed or pathfinder, the goal is the same—to reduce risk in the development of new aerospace technology.

Demonstration missions are becoming increasingly important in the U.S. defense/intelligence community for two reasons.

Artistic rendition of the Orbital Test Bed satellite. Image courtesy of NASA + JPL.

First, this community is under constant pressure to develop new space-based solutions in response to continually evolving world situations. Solutions must be developed quickly.

Second, the costs of engineering, building, and launching large complex satellites are climbing steeply at a time when budgets across the board are being cut. The risk of launching an untested sensor aboard a billion-dollar satellite is simply too great.

Test beds and pathfinders address these issues. As is the case with the OTB, the new clock is being flown on a space-proven satellite design, minimizing the chance of a bus failure. Moreover, existing satellite designs in the commercial sector are often selected because they are built with off-the-shelf components, which means they can be assembled and launched quickly, allowing new engineering concepts to go from the drawing board to orbit in as little as 12 to 24 months.

Increasingly, organizations in the defense/intelligence sector are tapping satellites in the 100- to 600-kilogram class for their demonstration missions. Much less complex than their larger multi-function counterparts, these satellites have price tags ideally suited for experimentation. Depending on the cost of sensors or subsystems being tested, a complete pathfinder mission could be launched for less than one-tenth the cost of an operational satellite.

For further information, access the SST-US infosite at: http://www.sst-us.com/

About the author

Dr. John Paffett is chief executive officer for Surrey Satellite Technology US LLC (SST-US), the United States subsidiary of world-leading small satellite manufacturer Surrey Satellite Technology Limited (SSTL). SST-US was created to serve the U.S. market with rapid, cost-effective small satellite systems, applications, and services. Paffet is also director of telecommunications and navigation for SSTL and chief executive officer of Surrey Satellite Services Limited, the SSTL subsidiary responsible for provision of launch service activities. He holds a bachelor’s degree (honors) in electronic engineering and a doctorate in electronic engineering from the University of Surrey.