Geographically Separate Units (GSU) leverage partnerships to ensure Space Systems Command is at the forefront of emerging Technology

The USSF’s Space Systems Command (SSC) may have its headquarters at the Los Angeles Air Force Base, but it also depends on the work of thousands of Guardians at its Geographically Separate Units (GSUs) around the country. These units fall under the SSC organizational structure and perform space-related work in a variety of fields at multiple locations.

Space Launch Delta 30, located at Vandenberg Space Force Base, and Space Launch Delta 45, located at Patrick Space Force Base and Ascension Island, are among SSC’s more than 25 GSUs at 14 different locations.

One of SSC’s l a r g e s t GSUs is the Innovation and Prototyping Directorate (SSC Det- 1) at Kirtland AFB, which includes two more GSUs — the Tools, Applications and Processing Laboratory (TAP Lab) in Boulder, Colorado, and the Space Test Program (STP) Human Spaceflight Payloads branch located at NASA’s Johnson Space Center (JSC) Author: United States Space Force (USSF) Space Systems Command (SSC) Geographically Separate Units (GSU) leverage partnerships to ensure Space Systems Command is at the forefront of emerging Technology Spelling Innovation With Three Letters: GSU in Houston, Texas. The STP branch in Houston is an Operating Location, the smallest type of GSU.

“The TAP Lab in Boulder, Colo. represents one of SSC’s GSUs at the forefront of U.S. Space Force’s innovation strategy,” said Steven Polliard, director of the TAP Lab, a government-operated, remote sensing, data exploitation research, development, test and evaluation (RDT&E) facility. The location earned accolades while previously functioning as a backup facility for all Overhead Persistent Infrared (OPIR) satellite data. “U.S. Air Force leaders chose Boulder in 2015 to establish the TAP Lab where it could leverage a unique series of existing investments in facility, infrastructure, physical and cybersecurity measures,” Polliard said.

Steven Polliard

The planned ramp-down of the Space Based Infrared Systems (SBIRS) activities — being replaced by the Next-Gen OPIR system — created the opportunity to stand up an all-new, RDT&E environment to exploit data and unlock more value from sensors in space.

The Boulder location provides proximity to TAP Lab’s operations mission partners at Buckley Space Force Base and also places the lab squarely in Colorado’s front range “Aerospace Alley” with hundreds of technology, defense and aerospace firms and research institutions, such as the University of Colorado, Boulder.

“When we were standing up the TAP Lab, the vision was: we are using this sensor data to enhance our primary missions – missile warning, missile defense and battle space awareness – but isn’t there some other value that we can squeeze from the data to support other mission areas?” Polliard said.

For example, the TAP Lab also provides a secondary source of weather data to U.S. Navy ships at sea, as a back-up to commercial weather sensors the Navy doesn’t own or control, Polliard explained.

Data Mapping + Crucial Capabilities

“Our primary mission is to rapidly develop and deploy high-value data exploitation algorithms and software applications using modern, innovative methods,” Polliard said. “Software applications address emerging, time-critical and challenging threats. They do this by ‘squeezing out’ critical knowledge from data collected by DoD and other satellites, including environmental sensors, such as GOES, VIIRS, MARK-IVB and potential future Environmental Weather Sensor (EWS) programs. We’re leveraging multiple sensor data to fill gaps in our data and to fuse to create new data, to improve and enhance our mission areas and those of other stakeholders.”

Much of the lab’s space data is archived and time-stamped and is used to help keep transactions consistent as they are mapped to each other. Major Evan M. Porter, deputy chief for data exploitation for the Technology Evolution branch, compared it to two people, standing at opposite ends of a long hallway, looking at an object in the middle of the hallway, from different vantage points.

“Even though they have different perspectives, it’s the same piece of information that they’re looking at,” Porter said. “It’s important when we’re exploiting data from often different sensors, that the data is marked, archived and time-stamped so when different parties are trying to access that data, they’re getting the correct data at the right time, even though they may be looking at it from different mediums. Not only does this provide the ability to properly warehouse the data but it allows the user to ensure accuracy of the data across all sensors.”

The TAP Lab, located in Boulder, Colo., is one of Space Systems

Command’s Geographically Separated Units. The government-

operated remote sensing data exploitation research, development, test

and evaluation (RDT&E) facility takes data collected from DoD and

other satellites and uses high-value data exploitation algorithms and

software applications to improve and enhance data for the warfighter

and other DoD and civil agencies. Photo courtesy of TAP Lab.

TAP Lab’s in-house software factory team is complemented by more than two dozen external vendors, ranging from small start-ups to major companies, academic partners and other government entities, all working in an open framework, collaborative environment.

The TAP Lab is directly staffed by military and government civilians, and organically staffed with Aerospace, MITRE, Software Engineering Institute, SE&I, and SETA personnel and provides access to top experts in their fields, creating the perfect environment for cooperation in ongoing research and development.

Space Test Program, The Backbone of Experimental Scientific Payloads Based at NASA’s JSC in Houston, Texas, the Space Test Program’s (STP) Human Spaceflight Payloads branch is focused on the acquisition, integration and environmental testing of payloads that host U.S. Department of Defense experiments for launch to the International Space Station (ISS).

The DoD’s STP has been sending experimental scientific payloads into space since 1965. To date, STP has executed more than 289 missions and provided spaceflight for more than 636 DoD experiments.

Craig R. Lamb

“The Space Test Program is the longest-running space program in the U.S. Department of Defense and is the second-longest program in the DoD, after the B-52 program,” said Craig R. Lamb, director, DoD Human Spaceflight Payloads. “There isn’t a single major operational system that Space Systems Command has developed that hasn’t been influenced by STP. The R&D technology that STP flies proves these new, emerging technologies for future DoD space systems and that’s important especially in today’s era, where the threat is greatly increasing in space.”

“We’re leveraging multiple sensor data to fill gaps in

our data and to fuse to create new data, to improve

and enhance our mission areas and those of other stakeholders.”

— Steven Polliard, Director of SSC’s TAP Lab, RDT&E facility

The Global Positioning System (GPS)that people take for granted today was developed from an STP experiment and is still provided via a DoD satellite constellation, managed by the United States Space Force (USSF), and provided to the public at no cost to the users, Lamb noted.

STP executes its mission from two locations. Headquarters are located at SSC’s Det-1 at Kirtland AFB and runs the overall Space Test Program and executes expendable launch vehicle missions such as the STP-3 mission with the STPSat-6 as its primary payload, as well as small launch vehicle missions such as the Rapid Agile Launch Initiative that fosters growth of the commercial small launch industry. STP’s Kirtland office also conducts suborbital sounding rocket missions, missions requiring geosynchronous access, and develops small spacecraft to host DoD experiments.

STPSat-6‘s nine payloads include the National Nuclear Security

Administration (NNSA)’s Space and Atmospheric Burst Reporting

System (SABRS), NASA’s Laser Communications Relay Demonstration

(LCRD) and seven Space Experiments Review Board (SERB) payloads

that demonstrate cutting edge space technologies. Artistic rendition is

courtesy of Northrop Grumman.

STP’s Operating Location, based at NASA’s Johnson Space Center executes STP missions that fly to, and operate from, the ISS. The STP Operating Location in Houston has a variety of ways to test new technology, including flying experiments in microgravity on reduced-gravity aircraft and sending experiments to the ISS, to be run either inside the station, or outside, attached to external modules.

“We are partnering with NASA and the space station program to get DoD STP technology tested in a very quick and cost-effective way,” Lamb said. “We’ve developed a pallet that you can fly to the ISS, plug into the side of the space station and you can test new sensors, new techniques of remote sensing, new pieces of hardware and we don’t have to build our own satellite to do that. We leverage NASA’s investment in the space station and get launched on commercial launch vehicles like the Falcon 9.”

Reducing Time and Cost with Reuse... and Partners

“We’re able to go from a paper concept to a payload in space in just a couple of years and get researchers the data they need,” Lamb said. “The program also uses reusable avionics to further cut costs and time. We’re taking the same flight computer, the same software, the same power converters, the same basic designs and we’re flying those time and time again, to save on that development effort,” Lamb said. “We’re reducing the time it takes us to build payloads that fly in space and we can get data faster and get research done faster so new technology can go into new operational systems faster.” In some cases, the STP program saves money by identifying technology that doesn’t work, Lamb said.

“Even if an experiment proves that this technology is not useful, it can save SSC or the DoD time and effort in not investing in technology that does not have a future,” Lamb said. “If you’re in charge of a multi-billion dollar program, you don’t want to take that risk of a new technology on that program. Programs need to have that technology demonstrated in space before they can build it into an operational system. You can’t afford to have that operational system fail – but you can afford to have an R&D experiment fail.”

AFRL’s Roll-out Solar Array (ROSA), developed in partnership with Deployable Space Systems in flight-testing on the ISS. ROSA offers scalable solar power array technology from hundreds of watts to megawatt range. Photo is courtesy of NASA.

Similar to the TAP Lab, STP works with a multitude of partners. STP is a DoD program, which means it flies experiments from the U.S. Army, U.S. Air Force, U.S. Space Force, U.S. Navy and other DoD agencies such as DARPA (Defense Advanced Research Projects Agency).

The agencies meet once a year with the Space Experiments Review Board to discuss and review the research projects they want STP to test, and rank them in order of priority. STP then tests as many of them as possible.

“The DoD and NASA have different missions in space, but both agencies operate in the space environment,” Lamb said. “There’s often cross-collaboration between agencies.”

One example of successful interagency cooperation is the Roll Out Solar Array, or ROSA, which started out with NASA and the Air Force Research Laboratory (AFRL) working together to find a way to make solar arrays more energy-efficient, lighter, and more dependable, Lamb said.

The ROSA technology was first tested in vacuum chambers on Earth, then sent into space on an STP mission in 2017, where the project was tested to see how it functioned in space and responded to vibrations and stress loads from ISS maneuvers. It worked so well that, in June of 2021, two new solar iROSA panels were installed on the ISS, the first of a six-panel, 120-kilowatt upgrade. The new technology also will be used on NASA’s Lunar Gateway project in the future, Lamb said.

“It’s not just about new solar cell technology,

but what that technology enables the satellite to do.”

— Craig R. Lamb, Director, DoD Human Spaceflight.

“Everyone wants better solar arrays — whether it’s on a DoD satellite or a NASA space station,” Lamb said. “Everyone wants more power for the mass: in the old days, you were lucky to get 12 percent of the energy that fell on a square foot of solar array, and now, with new technology - largely from space R&D – 33 to 34 percent of the sun’s energy can be converted to electricity and the ROSA technology reduces the mass needed so that more mass can be allocated to other spacecraft systems.”

He added, “If you have a communications satellite, and you can put more energy into your signal, that means your antennas on the ground can be smaller and you can get more data from space to ground. It’s not just about new solar cell technology, but what that technology enables the satellite to do.”

STP’s Houston branch’s latest mission, STP-H7 and STP-H-8, which launched in December on NASA’s SpaceX-24 resupply mission, sent nine DoD experiments to the ISS: six oneyear experiments, and three three-year experiments.

The payloads were installed on the Japanese (JAXA) and the European Space Agency (ESA)’s Columbus experiment modules on board the ISS and will run experiments demonstrating new technologies in surface wind detection, radiation sensors and space domain awareness and more.

Innovation + Prototyping

SSC’s Innovation and Prototyping Directorate is headquartered at Kirtland Air Force Base, New Mexico, and executes diverse missions not only from Kirtland, but also from various locations, including Los Angeles Air Force Base, California; Johnson Space Center, Houston, Texas; and three locations in Colorado — Schriever Space Force Base, Buckley Space Force Base, and Boulder, respectively.

The directorate’s primary mission areas include rapid prototyping development, prototype space operations, worldwide deployable telemetry, tracking, and control, prototyping capability maturation, and executing the DoD Space Test Program.

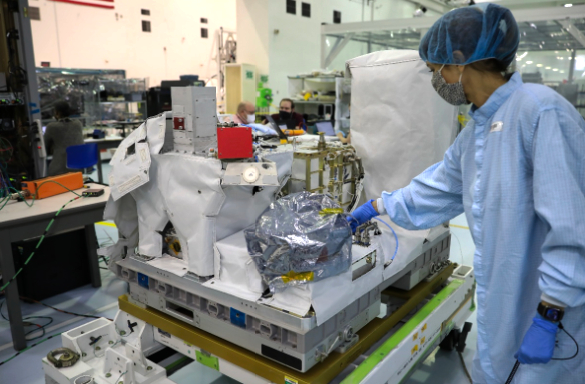

SSC’s Space Test Program H7 platform is shown being prepared for loading aboard SpaceX’s Dragon Trunk before the December 2021 launch to the International Space Station. Photo courtesy SSC Space Test Program.

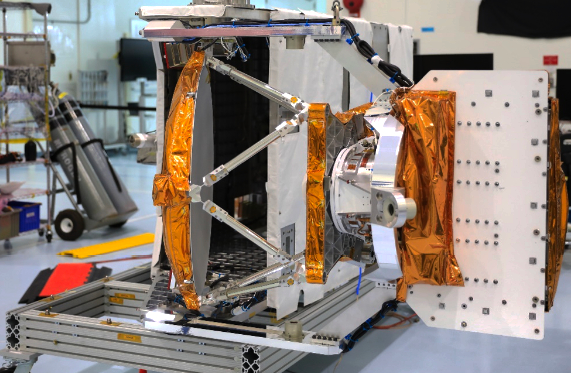

SSC’s Space Test Program H8 platform is shown being prepared for loading aboard SpaceX’s Dragon Trunk before launch to the International Space Station. The launch, on Dec. 21, 2021 was successful and both platforms were delivered to the ISS. Photo courtesy SSC Space Test Program.

The directorate is leading the way on enabling and delivering next-generation space enterprise solutions through rapid, innovative and affordable technology that leverages international, commercial, and interagency partnerships.

Space Systems Command is the U.S. Space Force field command responsible for rapidly identifying, prototyping and fielding resilient space capabilities for joint warfighters.

SSC delivers sustainable joint space warfighting capabilities to defend the nation and its allies while disrupting adversaries in the contested space domain.

SSC mission areas include launch acquisition and operations; space domain awareness; positioning, navigation and timing; missile warning; satellite communication; and crossmission ground, command and control and data.

Contact Space Systems Command at SSC@spaceforce.mil — also follow on LinkedIn.