In previous Government Satellite Report (GSR) reports, the discussion at a Washington Space Business Roundtable (WSBR — www.wsbr.org) event that featured an all-star panel of space experts discussing on orbit servicing of satellites has been reported.

Artistic rendition of NASA’s Restore-L spacecraft, based on SSL’s 1300 spacecraft bus, with the servicer extending its robotic arm to grasp and refuel a client satellite on orbit. Image is courtesy of NASA.

During that discussion, the panel talked about why these capabilities are enticing to military and commercial satellite operators and the steps that industry and government organizations have made towards making on orbit servicing a reality.

Following that discussion, GSR contacted Dr. Gordon Roesler, who has been at the forefront of many of DARPA’s (www.darpa.mil/) on orbit servicing initiatives and programs.

During this conversation with Dr. Roesler, the objective was to learn more about how far on orbit servicing technologies and capabilities have progressed and to obtain a better picture of what on orbit servicing can enable in the future.

In part one of this two-part conversation with Dr. Roesler the following topics were addressed; the current state of on orbit servicing; what future generations of this technology will enable; and why on orbit servicing is in such high demand. The following are Gordon’s responses:

Government Satellite Report (GSR)

Where does on orbit servicing currently stand? Is this science fiction, or are we rapidly approaching a reality where satellites can be refueled and repaired in space? And, importantly, how long until we get there?

Dr. Roesler

As we move forward, there are going to be generations of servicing that offer increasingly sophisticated capabilities.

Generation One is what I call simple life extension and there are already a couple of established players in that field.

Effective Space (www.effective.space/ ) is a UK organization that is building satellites that go up and dock with operating commercial communication satellites and help them maintain their positions and conserve their fuel, so that’s life extension through fuel conservation.

Orbital ATK (www.orbitalatk.com) is doing something similar with their Mission Extension Vehicle (MEV).

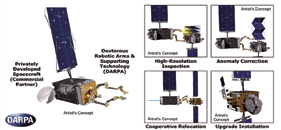

Generation Two is what DARPA is working on. We’re looking to use very sophisticated robotics to do things beyond just life extension. Using robotics, we’re looking to perform ultra close inspections, use robotic arms to repair satellites that aren’t functioning properly, or even perform upgrades — such as adding a new module to an operating spacecraft.

In terms of timing, Gen One is slated to launch in the 2018 to 2020 time frame and DARPA’s Gen Two servicer is going to launch in 2021.

I should also mention the NASA Restore-L effort, which blends Gen One and Gen Two technologies and capabilities. This is a spacecraft that uses a DARPA robotic arm in order to refuel a NASA satellite. That’s effectively providing a Gen One service with a Gen Two technology.

GSR

What are the commercial benefits of on orbit servicing? Why are commercial satellite operators interested in this capability?

Dr. Roesler

Let’s look at this in terms of the same Gen One and Gen Two breakout.

Effective Space’ SPACE DRONE™.

When it comes to Gen One, life extension is a big reason for commercial interest. Life extension will provide an operator with fleet flexibility. Take, for example, SES, which has around 50 [satellites] in operation; if they can keep one of those on orbit longer than was expected, they can shuffle the fleet around and provide services in a much more flexible way.

Simultaneously, this offers the benefit of minimizing capital expenditures by filling any gaps that might occur in the fleet without having to build an entirely new satellite — the Gen One services are very valuable to commercial satellite operators.

Gen Two [on orbit servicing] provides even more opportunity. Think about being able to bring up a new payload and attaching it to an existing satellite. Rather than having [to build] a new satellite to provide that capability, the operator only has to build a new payload. Not only does it defer capital expenditure, it actually reduces it.

This kind of idea of replacing payloads on orbit also allows the operators to keep up with the needs of the terrestrial customer base.

A satellite’s estimated life is around 15 years. That’s a long time to predict and understand what your customer base is going to look like or need. The ability to easily adjust the payloads in sync with customers can help keep the business case for that satellite alive.

Then there’s this idea of being able to perform repairs. About once every two years, a commercial satellite goes up and has some sort of deployment anomaly. If that could be repaired, not only does that allow you to recover the satellite capability faster than by building and launching a new spacecraft, but it also reduces insurance claims payouts. It’s really a win-win — there’s a host of benefits from the development and introduction of Gen Two capabilities.

GSR

How do those benefits compare with the federal government and military? Are the benefits for them the same? Are there other reasons why they’re interested in this?

Artistic rendition of Orbital ATK’s Mission Extension Pods (MEPs)™, which is a smaller and less expensive life extension service that performs orbit control

Dr. Roesler

Every one of those benefits that I mentioned also pertains to the U.S. government. The fleet flexibility and the reduced capital expenditures. We don’t have insurance companies — our insurance is from the taxpayers, so if we can save them the cost of a new satellite by repairing an anomaly, that’s a benefit as well.

There is also the ability to protect and provide resilience to our government satellites. An ultra close inspection with a robotic arm can help operators differentiate between an engineering flaw and a hostile act and that could help to maintain rational behavior. When things fail and we don’t understand why they fail, we tend to be suspicious — that’s just the nature of it. This could alleviate that suspicion.

There is a strategic benefit to this ultra close inspection. Also, there’s the benefit of being able to include new capabilities for protection of our existing satellites, as well as all the other benefits in terms of longevity and flexibility and repair.

GSR

Gen One and Gen Two on orbit servicing has been covered; however, what does the future after those two generations resemble?

Dr. Roesler

With the introduction of Gen Two capabilities, we’ll have access to dexterous robotics that can make something such as changing out a reflector to address a new service area [will be] something that’s relatively easy to do.

For example, the Dragonfly Project, a NASA-funded program, is intending to take reflectors and put them in place with a robotic arm on a commercial communication satellite. If you can put that in place with a robotic arm, you can also take it off again and put a different reflector on. That will give operators the ability to change the property of the satellite payload on orbit. To better enable that, there are some easy things we could start doing to our new satellites that would allow us to take more advantage of robotic capabilities.

For example, NASA Goddard has developed a refueling quick disconnect. Today there are still many steps required to refuel a satellite, but this quick disconnect greatly cuts down that number of steps. That quick disconnect would have to be integrated into the satellite design before launch, but it’s not a painful installation and it could greatly facilitate the ability to transfer fuel.

Another new addition we should be considering adding to satellites during design and construction is the equivalent of a USB port that most have on their laptops. This is something DARPA has developed for the servicer, but it can also be installed on satellites prior to launch.

With a USB port, you can plug in to a thumb drive or hard drive and it recognizes what the component is and it provides new services.

DARPA’s port will be used to hold the robotic tools on the servicer, but it also has power and data feeds just like a USB port. You could bring up a new payload, plug it in, and take advantage of the power and communications of the host satellite.

That’s when you’re starting to get into Generation Three, which we haven’t discussed yet — modular satellites.

There is a tremendous amount of research and development that still needs to be done to create a truly modular satellite. But that research and development is extremely valuable because, if you have a modular satellite, you can take advantage of a lower cost, and more prolific launch systems that are being developed.

Modular satellites would be assembled on orbit from components sent up on low-cost launches, or modules could be replaced in the future on a satellite that you have already built and launched. That said, there would be a lot of testing that would need to be done on the ground and a lot of progress needs to be made.

The other revolutionary Gen Three capability is the assembly of large structures, such as antennas and telescopes, in orbit. NASA is working on an orbit assembly for future astrophysics missions, on the premise that something large, such as a 20 meter telescope, must be assembled on orbit, due to the massive size of the hardware.

In those instances, there is no way you could fold it into a single launch fairing — so [the hardware] would need to be assembled robotically in space.

In the same way, being able to assemble the largest reflector or antenna possible would give communication service providers significantly more flexibility.

GSR

Looking back at Gen Two capabilities and the addition of payloads to existing satellites, what types of payloads and capabilities could be added to a satellite in space with this technology? Why is this an attractive option for the military? For commercial operators?

Dr. Roesler

There would be many different possibilities.

For example, one simple thing operators could do is to add cameras that provide the satellite the ability to see around it. In geosynchronous orbit, these satellites are 22,000 miles away and it’s difficult to see small objects. If these cameras could see small objects close to the satellite, it would give operators the ability to react appropriately.

One other capability that could be added is space weather sensors. I mentioned earlier the consequences of not knowing what caused an outage. If you built a space weather sensor and attached it on orbit, you’d have an indication of whether or not an outage was related to a solar event. There are also other ways of detecting nearby satellites that could be integrated into a small payload and attached.

The advantage of an attachable payload is that you don’t have to integrate it with a propulsion system and attitude control system. The cost is lower, it’s available for use faster, and the opportunities to get it on orbit are more numerous.

For example, DARPA has developed a capability called PODS — which stands for Payload Orbiting Delivery Systems — that could carry a wide variety of separable mass elements to orbit — including attachable payloads — aboard commercial communications satellites. With 15 commercial launches to GEO a year, we can take advantage of such methods to get small payloads up there without having to buy entire launch vehicles.

In terms of commercial offerings for attachable payloads, many have told me that they are excited about the opportunity to host some of these payloads. It will produce a revenue stream for them for sure, but it also allows them to start thinking about other approaches for fleet flexibility. This is also an entrepreneurial opportunity. There are people out there who want sensors for applications like agricultural use or environmental data collection, and some of these things can be done from GEO.

GSR

Something often heard reg timing concerns — not having payloads built in time for launch — which are a main reason why some agencies shy away from hosting payloads on commercial spacecraft. Could you see a reality where military or government payloads are placed on commercial spacecraft on orbit? Could this help alleviate some of those concerns and drive up adoption of hosted payloads?

Dr. Roesler

You really hit the nail on the head. Sometimes, secondary payloads, hosted payloads — or even the payloads for the primary mission — aren’t ready in time. The ability to add them after launch should be extremely freeing for the whole space enterprise and adds a tremendous amount of flexibility.

GSR

During the panel discussion, the panelists touched on the possibility of constructing satellites in space. Why would it be attractive to literally build or construct a satellite in space? What would that enable us to do that we can’t do with our current system of building satellites on Earth and launching them already constructed?

Dr. Roesler

One of the huge advantages is the reduction in testing and design requirements. If I’m going to launch something in pieces, I don’t have to worry about whether the entire assembly survives during launch — I only have to worry about whether the individual pieces survive. By testing at a lower level of integration, I’m saving costs and I’m saving time when I put them together on orbit.

Another thing that approach lets you do is change your mind. Say you’re building numerous satellites and you have a choice of payloads and maybe you have a choice of power systems. If you have a modular architecture, you can change your mind about what a particular satellite is going to be in real-time. That’s basically unheard of now.

And, as I mentioned earlier, there’s this idea of taking advantage of smaller launch vehicles. There’s a group of investors today that are developing launch vehicles of much lower capacity than available medium-lift ones.

Similarly, DARPA is working on a launch system called XSP, which stands for Experimental Spaceplane, which is going to put 3,000-5,000 pounds into LEO. That mass range fills a gap between the very small launch vehicles and the larger ones. By taking advantage of that emerging launch infrastructure that has a lot more variety to it, we get another reason to consider building satellites in orbit.

GSR

When it comes to all of these technologies and capabilities — on orbit refueling, on orbit servicing, adding payloads to existing satellites, building satellites in space — who is taking the lead in the development of these solutions?

Dr. Roesler

In the case of Gen One — life extension — it’s primarily industry. In the case of Gen Two — on orbit refueling and on orbit servicing — it’s definitely DARPA.

RSGS is a very large program dedicated to building a GEO robotic servicing vehicles and getting it on orbit quickly. When I say that, I should also mention our commercial partner, SSL, who is building the bus and the ground segment and will eventually operate the satellite. I should also mention the Naval Research Laboratory, which is responsible for all the advanced robotic work that’s leading to this capability. The technology is government-initiated, but we know that commercial players are eager to participate.

Looking at Gen Three, I would say it’s a combination of DARPA, NASA, and industry. DARPA has some small projects centered around on orbit assembly and also the idea of putting a persistent platform into GEO. One where payloads can come and go.

The analogy I like to use for such a platform is the antenna tower that you see along the highways. When you look at one of those towers, you’ll see a number of devices — cellphone antennas, point-to-point microwave, public safety radio antennas — all hanging on it. That’s because it’s less expensive to pay rent to the tower owner than it is to buy land and build a tower.

Obviously that makes sense in GEO as well. If you can just send up a payload to a persistent platform, you don’t have to worry about propulsion and attitude control. You have all that provided by the platform and you pay a fee to the platform operator for hosting your payload. That’s really a win-win.

It could also provide flexibility, being able to swap the payloads more frequently and not have to worry about what the market is going to be like a few years from now.

For additional information on DARPA’s on orbit servicing programs, please view www.darpa.mil/program/robotic-servicing-of-geosynchronous-satellites

This article is republished, courtesy of The Government Satellite Report (GSR) and Executive Editor Ryan Schradin. He is a communications expert and journalist with more than a decade of experience and has edited and contributed to multiple, popular, online trade publications that are focused on government technology, satellite, unified communications and network infrastructure. His work includes editing and writing for the GovSat Report, The Modern Network, Public Sector View, and Cloud Sprawl.

His work for the Government Satellite Report includes editing content, establishing editorial direction, contributing articles about satellite news and trends, and conducting written and podcast interviews. Ryan also contributes to the publication’s industry events and conference coverage, providing in-depth reporting from leading satellite shows.

The Government Satellite Report is sponsored by SES Government Solutions

www.ses-gs.com