Before the last Space Based Infrared System Geosynchronous Earth Orbit (SBIRS GEO) satellite is launched into space in a few months, one of the final stages of the process will be the encapsulation in May.

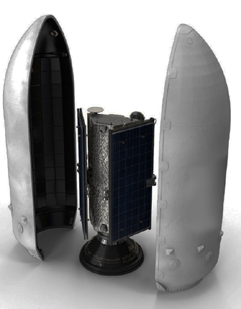

Encapsulation is when the payload — a satellite, piece of scientific instrument or other item to be launched into space — is surrounded by the “fairing” — a smooth, protective cover placed around the payload which protects it while reducing atmospheric drag on the rocket as it is launched into space.

Lt. Col. Matt Flahive

“The fairing protects the satellite vehicle during the ascent,” said Lt. Col. Matt Flahive, Materiel Leader, Atlas V Launch System at SSC, who works with United Launch Alliance (ULA) on Space Systems Command (SSC) launches. “You’re passing through the atmosphere at a high rate of speed so there are heating and environmental concerns. The flight computer calculates when free molecular heating drops below a predetermined limit, and then commands the payload fairing to pyrotechnically ‘unzip.’ Performance of the payload fairing is critical to providing the mission assurance we need for our payloads.”

Lt. Col. Ryan C.

Laughton

“This is the last opportunity to really work on the spacecraft,” said Lt. Col. Ryan C. Laughton, Materiel Leader, SBIRS GEO-5/6 Production at SSC. “It’s the last time most of the workers will lay eyes on the satellite before it’s launched into space. Fairings are an absolutely vital part of the rocket and satellite build, and encapsulation signifies the end of production for the satellite and the start of the final stages of launch preparations.”

This particular upcoming launch will be notable for being the sixth and final launch of the SBIRS series of satellites that provide missile warning, missile defense, technical intelligence and battlespace awareness data to the warfighter. [SSC’s Next Gen OPIR satellite constellation, now in production, will eventually replace SBIRS.] SBIRS GEO 5 was launched in May of 2021, and operational control was transferred from SSC to Space Operations Command in February of 2022.

Like the previous SBIRS satellite, GEO 6 is based on Lockheed Martin Space’s modernized LM 2100 spacecraft — an update that improves overall system production, affordability, and resiliency to provide overhead persistent infrared capabilities to U.S. warfighters and allies. The “world class” sensors for the satellite were built by Northrop Grumman, Laughton said. United Launch Alliance is the launch vehicle provider for GEO 6, just as it was for GEO 5.

“Encapsulation is the start of our integrated operations,” Flahive explained. “The space vehicle and launch vehicle teams work together in the payload processing facility and they work in concert to complete the encapsulation, rolling into when we mate the encapsulated assembly to the launch vehicle, creating the rocket stack.”

“Nothing bonds a team together like launch because you’re working through challenges and the ultimate goal is to get that satellite on orbit through this high- risk period,” Laughton said. “These days, the fairing is likely to enclose multiple expensive, delicate payloads. For the SBIRS GEO-6 satellite, the airtight fairing will keep the satellite at a precise temperature and humidity for the entire period the space vehicle is on the ground until fairing separates.”

“We only use the fairing for just a few minutes during launch and then they’re jettisoned, but we’re encapsulating the payload for two to three weeks on the ground, and it provides that critical ground environment,” Laughton said. “The fairings have to be strong but light — the heavier the fairing, the less payload you can get to orbit. They have to be air-tight and provide that secure environment. It’s truly remarkable that we’re able to do that. It’s a work of art and a work of science to get it just right.”

The encapsulation process will begin with the satellite being shipped to the National Reconnaissance Office’s (NRO) secure integration facility in Florida, several months before the launch. There, it will be checked thoroughly and tested in a clean-room environment before being surrounded by the fairing, Laughton said.

“We are laser-focused on cleanliness and contamination requirements,” Flahive said. “We aim to protect the satellite vehicle throughout the entire process.”

Dr. Walt Lauderdale

“Access to the spacecraft is severely restricted after encapsulation,” said Dr. Walt Lauderdale, chief, Falcon Division with SSC’s Launch Enterprise, who works with SpaceX. “Depending on the program, there may be some things they need to access through small doors in the payload fairing prior to launch, but for the most part, you’re done with the major processing of the spacecraft. It’s like sealing up a package for delivery.”

“The integrated operations include performing numerous tests to simulate the entire mission to make sure all the commands are planned and executed appropriately,” Flahive said. “It typically takes approximately a week to 10 days for the encapsulation process to be completed.”

“We test the satellite before we encapsulate it to make sure there’s been no damage in shipping and then once that’s complete, we fuel it,” Laughton said. “Once you fuel it, almost anything you do becomes hazardous, so we have to limit the amount of movement. A few weeks later, after encapsulation, we move it onto the launch pad and then there will be more testing. Testing is crucial because there is no room for error. In addition to making sure the satellite and other payloads will arrive safely in orbit, the teams are aware that launch slots are in short supply and coveted, so the launch must go perfectly.”

Artistic rendition of how a satellite is

surrounded by the fairing, before being

placed at the top of the rocket for launch.

“We don’t get a second chance,” Lauderdale said. “Unlike an airplane, where you might lose an engine and still be able to land, we don’t have that for our payloads. If the rocket has a big problem, that payload is dead.”

Artistic rendition of how a satellite is surrounded by the fairing, before being placed at the top of the rocket for launch. “The number one goal for my team is to keep the satellite safe, and then once it’s out to the pad, you want to keep the launch vehicle and the satellite safe,” Laughton said. “It takes both the launch vehicle and the space vehicle teams to make this happen.”

Hosting a suite of sophisticated heat-seeking sensors,

the Space Force’s fifth Space Based Infrared System

(SBIRS) satellite took off from pad 41 on Florida’s

Space Coast on an Atlas 5 rocket last year. SBIRS

GEO 6, the last in the series, will launch later this

summer. Photo is courtesy of SSC.

The encapsulated assembly will then leave the NRO facility and be transported several miles to the vertical integration facility, Laughton said. Once we get it out there, a large crane carefully picks up the entire encapsulated assembly and pulls it several hundred feet into the air to mate it on top of the launch vehicle. The launch vehicle isn’t fully fueled at this point, but it’s still a delicate operation because the encapsulated assembly has a lot of fuel in it.

“It’s important that we do it right; if we somehow damage the vertical integration facility, now we’ve prevented other missions behind us from launching on an Atlas until they get the facility repaired. That’s why we put so much care into it — all the missions behind us are counting on us to do it right,” Laughton said.

Launch tempo continues to increase. In 2021, Space Launch Delta 30 at Vandenberg Space Force Base had seven successful launches and is expected to have 22 this year. Space Launch Delta 45 at Patrick Space Force Base had 37 successful launches in 2021 and is expected to have 67 in 2022.

“When we work with SpaceX or ULA, we want them to succeed because everybody suffers when there’s a launch failure,” Lauderdale said. “It’s a full partnership and it’s critical to our national capability. Right now, when you look at what this country can do, and what critical capabilities it can deliver on orbit in order to meet the threat, it is stunning.”

Hosting a suite of sophisticated heat-seeking sensors, the Space Force’s fifth Space Based Infrared System (SBIRS) satellite took off from pad 41 on Florida’s Space Coast on an Atlas 5 rocket last year. SBIRS GEO 6, the last in the series, will launch later this summer.

Photo is courtesy of SSC.