Computers have been used to help design high-tech satellites for many years, but one Space Systems Command (SSC) project in particular is working to take digital engineering to the next level, officials said.

The Missile Track Custody Demonstration (MTCD) is a prototyping effort to determine possible future satellite constellations supporting SSC’s Missile Warning and Missile Tracking mission.

Lt. Col. Gary Goff

“The digital engineering sprint of the project, which was formally launched in May of 2021, is using digital engineering, modeling and simulation to validate requirements for missile raid containment while building flight demonstration units that will validate performance and feed data back into the digital models,” said Lt. Col. Gary Goff, materiel leader for rapid prototyping at SSC. “We look at the current missile threats that are out there – what they look like, how they fly, how they emit heat – and do a war-game simulation with them. Then we simulate what our sensors would see, how well we can track the position and velocity and contain them at a certain accuracy, and how we tell the radars on the ground where to search for an inbound missile so they can use that information to launch an intercept.

“The contractors are going to look at how they build that sensor, the optics it would take, the electronics it would take, the full satellite design and they’re going to represent that digitally and tie it back to the government requirements,” Goff explained. “This gives us the ability to do a full digital design. We call it ‘try before you buy’ — we’re going to show we can meet all these performance requirements before we go and start building it.”

Goff said there will be some smaller demonstrations of some of the electronics — which will serve to validate the performance of the digital models – but most of the project in the initial design phases will be digital.

“Let’s say that in your model, you thought that you could detect a certain missile, based on the way you simulated it,” Goff explained. “We’re going to put some of those electronics to the test on the ground in a live environment and be able to show if the performance matches the model prediction. This way, we tie the model to some real data.”

Joel Gussy

Joel Gussy, system director for demonstrations and technology programs for The Aerospace Corporation, the lead FFRDC (Federally Funded Research and Development Centers) organization on the project, said MTCD has two key aspects: development of a new space-based capability to track emerging missile threats, and a digital engineering approach that will capture the technical details in the model space to help design the system and analyze its performance. “I see three key elements to digital engineering that all need to be tightly integrated. There’s the model-based systems engineering models, then the detailed modeling, simulation and analysis tools and then there’s things like digital twins, where you have a representation of something that’s real built in a software model,” Gussy said.

The MTCD project is primarily focused on the first two elements now but is also pursuing targeted, digital, twin representations that will have a large payoff during later phases of the program, Gussy said.

MTCD has two prime development contractors: Millennium Space Systems (MSS) and Raytheon Intelligence and Space.

The effort includes integration of the model-based systems engineering data from the two payload contractors and other SSC Overhead Persistent Infrared (OPIR) programs in a Government Reference MBSE Model (GRMM). The MTCD GRMM will provide the government requirements, high-level architecture, internal/external interfaces and enterprise behavior.

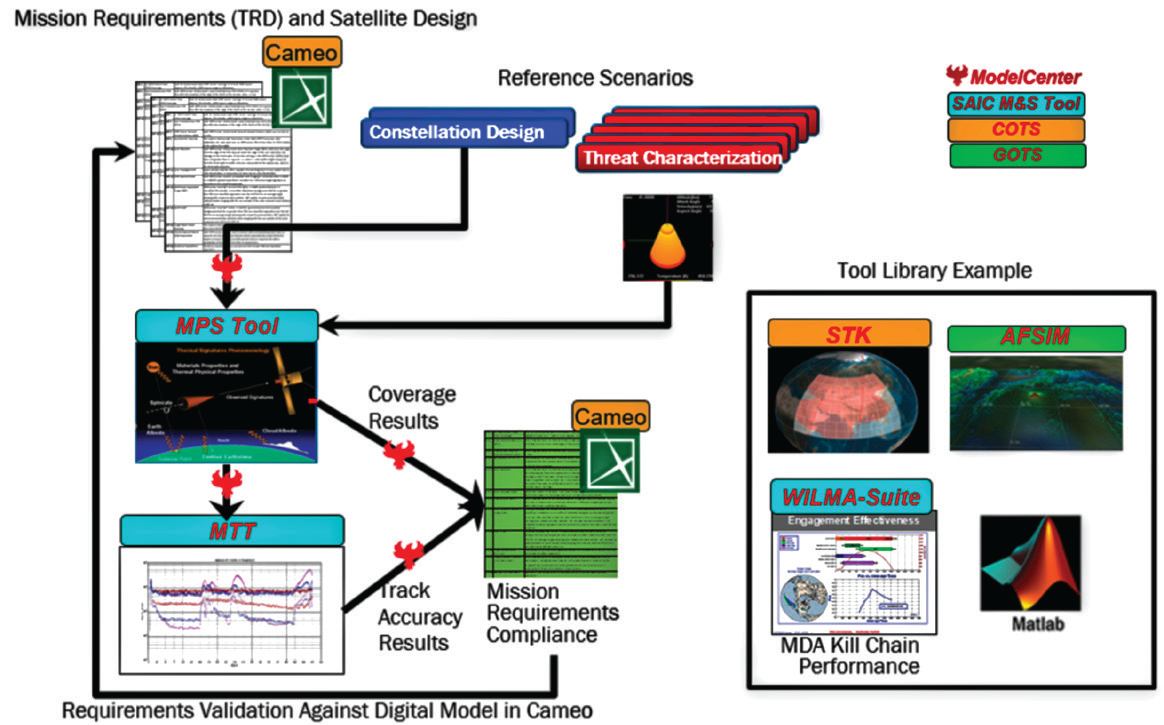

The methodology for both contractors to connect their models to the MTCD GRMM is through a Cameo Project Usage — a software package that handles system markup language, separate from the performance model — to ensure evaluation of each contractor’s solution against the same problem domain.

End-to-End digital thread example. Image is courtesy of SSC.

End-to-End digital thread example. Image is courtesy of SSC.

For most modern military programs, performance models and simulation tools are used to validate a contractor’s designs. However, MTCD is taking this practice one step further by connecting the performance and simulation capabilities to the model based system engineering models.

The Aerospace Corporation and Science Applications International Corporation (SAIC) models will be used to independently verify contractor performance results using the contractor’s system characteristics as defined in their model based system engineering models.

“A lot of folks associate digital engineering with model-based systems engineering, but I see that as just one piece,” Gussy said. “On this program, not only did we request model based systems engineering products from our industry partners, but a dozen specific analytical models that break down how their system and subsystems operate or interact with each other.

“These analytical models will allow us to execute the integrated modeling, simulation and analysis effort but also help pave

the way towards those digital twins,” Gussy said. “This gives us a methodology to represent the physical, functional and the performance aspects at a high level of fidelity. We’re not just doing the independent validation, but also helping to integrate the components of contractor development with the broader missile warning, tracking and defense enterprise, including the Missile Defense Agency and the Space Development Agency. How all those weapon systems will work together is something we can do efficiently with these digital models and performance simulations.”

Frank Macchia

“There’s a lot of talk about “digital twins” but the first step is a digital thread,” said Franco Macchia, systems engineer with SAIC, which also is working with SSC on a prototype missile warning sensor system for the project.

“If I have a system described in a model-based system engineering model and I want to run a trade-off analysis — maybe I want to add more satellites — those are threads you can test digitally and do a trade analysis very quickly,” Macchia said.

“Digital engineering is an enabler,” he added. “It can immediately help you manage and understand that system. Think about all the different connections and behaviors to everything else: you’re trying to model different communication links, satellite to ground, cross-links with other satellites – there’s a ton of information flowing. Using a model based systems engineering model helps to understand and capture a lot of information that’s very difficult to do with PowerPoint charts – and you can see where something is impacted as soon as you make a change.”

`Currently, Goff said, the project is undergoing its Preliminary Design Review. The team understands the requirements and is working on the preliminary design of the sensor itself. In November, the project will undergo an all-digital Critical Design Review (CDR) “in the model.”

“The whole purpose of that CDR means that we are ready to start building that sensor,” Goff said. “If we come out of that meeting and we agree that it can do everything we need it to do, we’ve shown it all works together, the next step is to start ordering parts and assembling the sensor and building satellites, targeting a launch as early as 2026.”

“Having a CDR with only digital deliverables is very unusual,” Macchia said. “Normally, you would do some R&D testing of hardware prior to the CDR. We’re evaluating these prototype systems entirely digitally, which is also, in a way, a prototype of the methodology for passing CDR without building system hardware. Our program is a major pathfinder for future SSC efforts.”

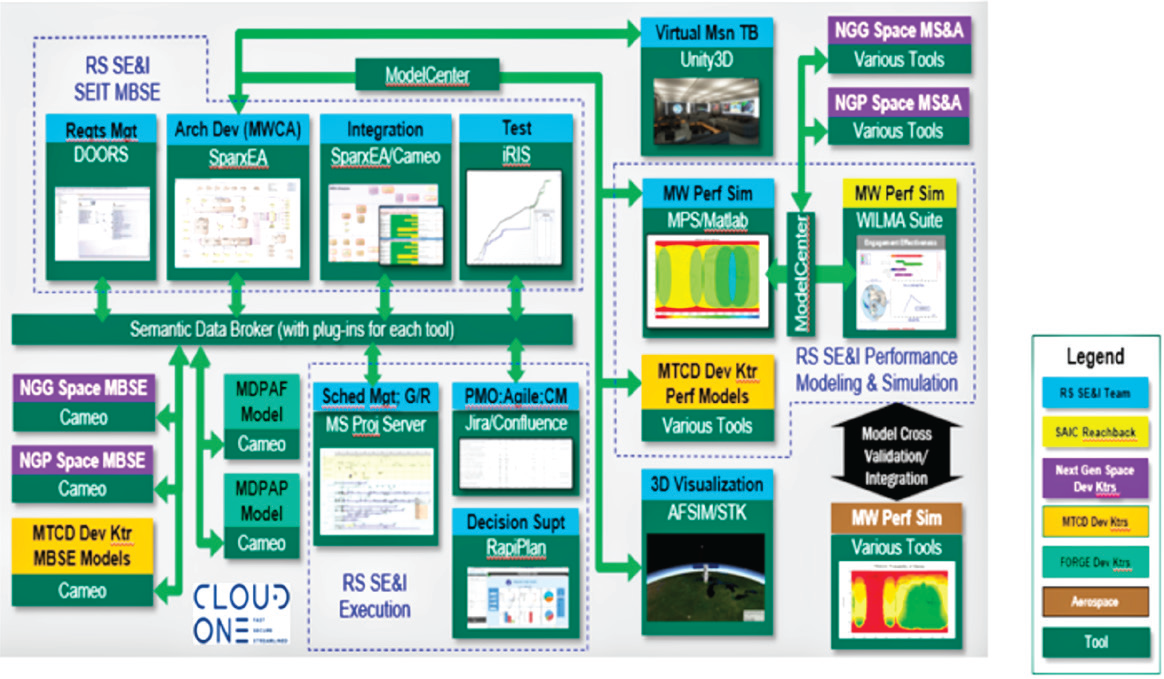

Missile Warning Future Digital Engineering Ecosystem. Image is courtesy of SSC.

Missile Warning Future Digital Engineering Ecosystem. Image is courtesy of SSC.

“At some point as part of this project, we’ll be able to take the models to a classified environment and we’ll be able to tie the performance models to a requirements-based model,” Goff said. “We’ll be able to do quick iterations and design trades, almost automatically. Say you want to launch another satellite; how much will that improve your performance? What if there’s a new missile? How can your system perform against that? Well, we will be able to do that very quickly and tie that right back to the war-fighter requirements.”

“As you move forward in a program, it becomes more complicated to integrate more systems as you fill it out and add more satellites, both from the ground perspective and the space perspective,” Goff said.

“One of the biggest benefits of using a digital model is being able to define all the appropriate interfaces and do all the integration work necessary. A lot of these sensors will be built by one contractor, maybe the bus will be built by another, and the ground system by a different contractor. You have the models tying together these different areas of expertise, across all these different contractors, and it gives you an ability to do that integration much more rapidly.”

The biggest barrier challenging the MTCD’s full implementation of the digital engineering approach is the lack of a collaborative digital environment. Currently, SSC government/contractor networks are mostly isolated from each other and do not have the capability to

use these tools and integrated threads in a common space. “We’re spending time on and investing in the infrastructure to allow us to have a secure environment to share and integrate these various products,” Gussy explained. “There’s different models and tools that come from the developers and products from the integrated government team that we want to tie and link together for the full system of systems assessment. We need a common shared environment we can do that in.”

MTCD is pursuing a Cloud-Based Digital Environment to provide broad access to all of the digital engineering and Modeling & Simulation (M&S) tools. The project is currently evaluating usage of the U.S. Department of Defense’s Cloud One’s Digital Engineering as a Service (DEaaS). MTCD also is looking into Direct Connect and Commercial Solutions for classified options to increase the speed at which connections to the Cloud can be made.

If the project is successful, it will be a game-changer for SSC, Goff said. “How it works now is, we have a government model, and sometimes we send that model over to the contractors on CDs, because it’s classified. If we’re able to interact in the Cloud, when

I come to work every day, I’m logging in to a set of software in a classified, Cloud-based environment and the contractor is logging on to the same Cloud-based environment.

“They’re doing their development, and the government is reviewing that development, different contractors are interacting together in the Cloud at a classified level,” Goff said. “There’s no awkward stage of delivering a model, figuring out the software, what patches you have, what you don’t have, what modules you need.”

It would also make it easier in the future for new, emerging and smaller commercial space companies to work with the USSF, Goff added. Currently, larger defense “primes” have an advantage because they have established relationships with the government, have personnel with security clearances and access to secure facilities. A secure Cloud environment could help smaller companies interact with the government at the right classification levels in a matter of months, not years.

Macchia said one misconception he often hears about model-based systems engineering modeling is that there are a lot of non- recoverable costs. However, a MBSE model can be generated fairly quickly with initial information, but then subject matter experts and engineering leads have to help refine that data, which can sometimes take weeks.

“The resource-intensive piece in understanding a system is still the Systems Engineering required to ensure that the model is accurate, not the actual modeling effort,” Macchia said. “The model is a tool to help organize the systems engineering and helps to catch any areas that were missed or do not make sense. In the long run, the model saves time and money by identifying optimal solutions that wouldn’t have been possible to, or would have been difficult to identify by traditional means.

“Additionally, once we build a model of the system(s), engineers can use the models for future programs — update them and build off of them,” Macchia said. “It’s a dynamic description, rather than a static one.”

Even with the advances in modeling and technology, human experts are still a critical component for success, Gussy said. “One thing that doesn’t get said enough about digital engineering is that there is still a need for the subject matter experts and the real engineering teams,” Gussy said. “Some people envision that you have all these models and you change a parameter and push a button and an optimized design gets spit out. We can do that for simple trades but we still have some work to go to automate for assessment of the

complex and dynamic mission systems and warfighting scenarios that we are dealing with here.

“We need the skilled engineering personnel and technical experts to help build the models, drive smart trades and evaluate and interpret the data and results,” Gussy said.