Off-air testing of ‘ground station’ equipment has come a long way since the dawn of geostationary satellite communications nearly half a century ago.

In those early days, the term ‘ground station’ meant precisely that — a large parabolic antenna along with the edifice’s transmit and receive electronics, firmly anchored into the Earth’s crust.

Each element of the station, more often than not a one-off design, would be individually tested before being assembled into a system. At that point, an occasional test on a less-than-overcrowded satellite transponder might be the final set up check before going live. Makeshift loop back tests using a basic RF mixer and microwave signal generator were also in evidence.

Today, the term ‘ground station’ has grown significantly in meaning to include any part of the link which is non-satellite. Mobility is the key word and, aided by the electronics miniaturization revolution, SATCOM-On-The-Move (SOTM) is a reality — platforms now including ships, aircraft, road vehicles, trains and manpacks.

Likewise, the testing of SATCOM systems has had to evolve to meet the needs of the modern user and, indeed, manufacturers. Equipment is now mass produced, on-satellite testing is frowned upon and the range of test parameters has outstripped the capabilities of that ‘good old’ mixer/LO check.

For the major terrestrial teleports, the rack mounted loop test translator still provides a cost-effective, easy-to-use, wired-in facility; however, attempting to use these, where the whole station is both compact and mobile, can be quite cumbersome.

What is required is a device that can quickly and efficiently test the entire system by accomplishing exactly what the satellite transponder does, but managing to do so locally and at a small fraction of the cost.

The UK based SATCOM RF Test company, AtlanTecRF, has pioneered the development of such instruments for several years with the company’s Satellite Simulator products, such as the firm’s LSS series, originally designed to tackle airborne, internet connectivity systems and its SNG series is driving down the cost of checking out van mounted news gathering rigs ready for broadcast, completed while the van is still in the depot.

Movement is the essence of the majority of current satellite communications systems and, therefore, test products have literally had to accommodate this trend. Carrying out the RF test while the platform is in transit has now become the order of the day, as antennas are often steerable, either mechanically or electronically, in order to keep the ‘Bird’ in view under all likely aspects.

To meet this challenge, AtlanTecRF has taken to the air with the company’s Satellite Simulators. New compact lightweight and high efficiency flight models for battery or solar operation are now being produced for carriage by airplanes, helicopters and balloons (both low and high altitude), in all cases pretending to be a satellite for the purposes of testing the full capabilities of the ground/ mobile based terminal.

There are further complications — suppose a surface based platform is large and set on a course —– a train or a large ship, for example. Going through the entire process of orientation of an antenna, all the while mounted on such a moving platform, would be unbelievably time-consuming and costly. If the platform cannot be easily maneuvered, then the test gear must be agile.

Enter the drone. These Unmanned Airborne Vehicles (UAVs) have the ability, under control from the ground, to dance around the sky, or more accurately fly around an antenna platform in a way that will directly mimic the altitude change of that platform in service, but without the need for extraneous diversions from the UAV’s normal course.

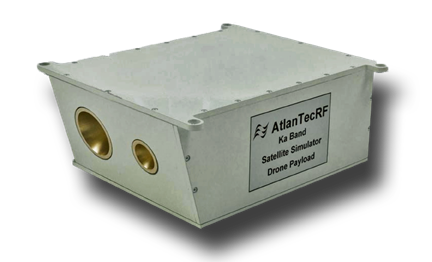

Designated the Drone Satellite Series (DSS Series), AtlantecRF’s addition to the growing family of satellite simulation and loop test products has become the ‘Sparrow’ fluttering around, essentially emulating the ‘Big Birds’ that sit 22,000 miles away (see Figure 1, above, which shows the DSS maneuvered to align with the ship’s antenna prior to testing. Maneuvering the drone enables the testing of the terminal satellite tracking).

The compatibility of this drone-mounted payload includes operation in either Ka-band (30 GHz uplink and 20 GHz downlink) or Ku-band (14 GHz uplink and 11 GHz downlink) with options of both circular and linear polarization.

In order to cover all of the probable operating frequencies of the antenna or system under test (AUT or SUT), the DSS may have a fixed turn-around or Local Oscillator (LO) frequency. In many cases, there will be a requirement for LO frequency tuning, which is effected by means of a low frequency command radio link to the drone. Data relating to the length and quality of the transmitted signal can also be gathered at the drone and returned to base via a telemetry channel.

In some cases, the DSS will draw its power from the same batteries providing lift to the UAV but it can also be supplied as self-sufficient with integral, rechargeable power storage.

Military Maneuvers

Such agility in SATCOM testing has obvious attractions for the military. The vast majority of systems for the army, navy, air force and marines are constantly on the move with little or no time available for testing and set up. Steerable antennas are commonly part of the kit and therefore AtlanTecRF’s DSS ‘Sparrows’ fulfill the test function in all respects of agility and speed.

Further, the Drone Satellite Simulator can have additional value in actually transmitting a signal from point A to point B, without using a satellite at all, across a small footprint, as might be found in an operational situation.

If, in that situation, there is no geostationary or Low Earth Orbit ‘Bird’ available, the DSS ‘Sparrow’ is launched to bridge that short-hop communications gap.

The DSS also has a role to play in the interception of enemy satellite transmissions, picking up the uplink from foe SATCOM stations and transmitting a downlink to a friendly receiver who can either listen in to gain advantage or, indeed, transmit back false data for confusion effects. The applications for the military are wide ranging and very cost effective.

AtlanTecRF’s ‘Sparrow’, a would-be ‘Eagle’, therefore provides a neat and economical solution to the testing of satellite communications terminals ‘on-the-move.’

AtlanTecRF is a leading global manufacturer of RF and microwave equipment, components and interconnects. The company specializes in providing SATCOM RF test equipment to the Military, Government and Commercial organizations.

The firm’s comprehensive range of equipment includes Loop Test Translators, Frequency Converters, Signal Generators, Noise Injection Translators, Noise Generators, Line Amplifiers and Satellite Simulators. Equipment covers bands L-, S-, C-, X-, Ku-, DBS-, Ka- and Q-.

Atlantecrf.com/satellite-equipment.htm

Geoff Burling is AtlanTecRF’s CEO. His role, to drive growth across all aspects of the business by bringing to market a range of new and high quality RF and microwave components, interconnects and equipment. Geoff sets the company’s long-term business strategy and takes the lead in building customer relationships and developing employees.

A passionate engineer, who uses his in depth knowledge and market expertise to ensure AtlanTecRF delivers the highest quality products, technical expertise and customer service demanded by today’s engineers.